When technology goes down the drain

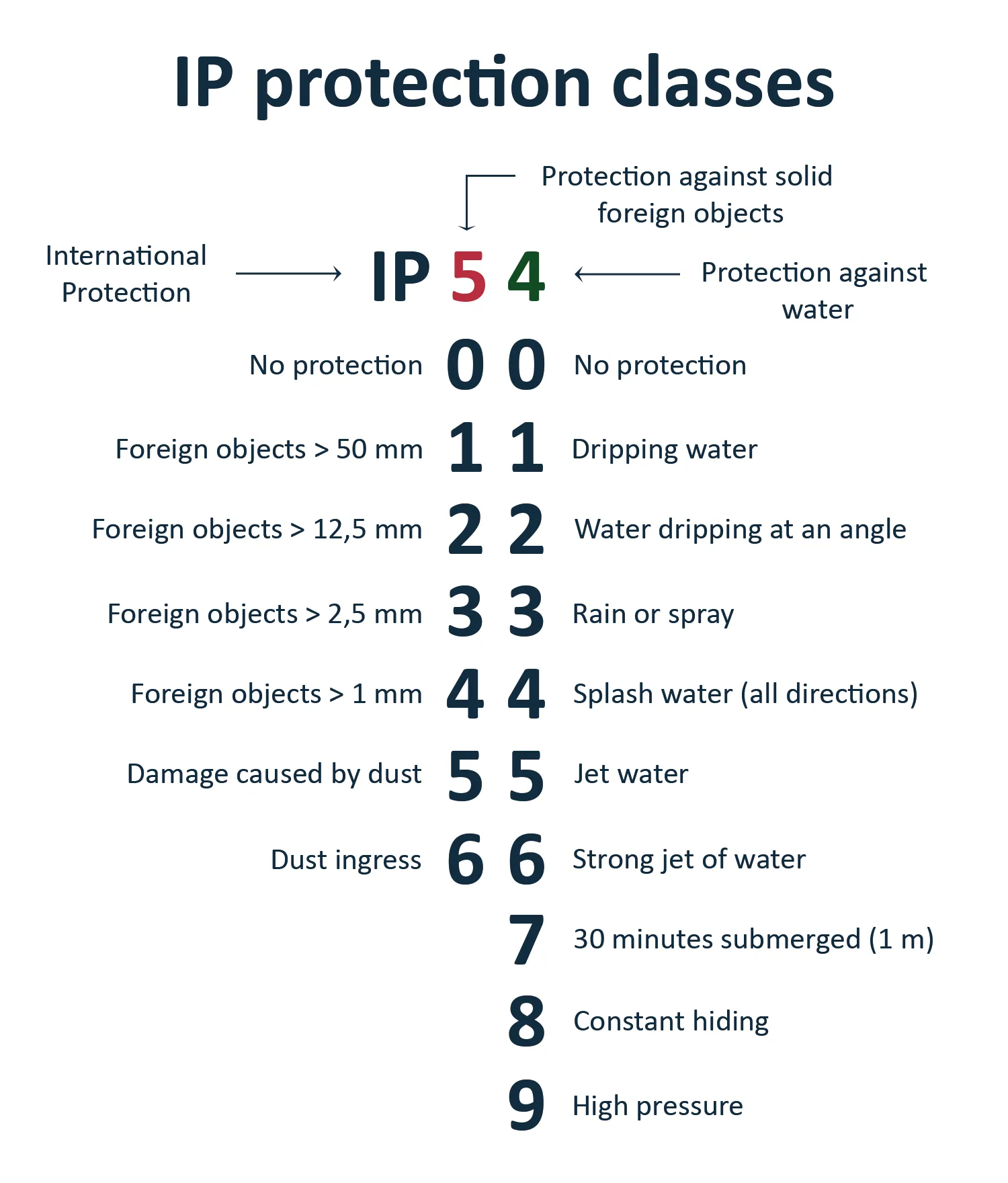

It may sound like a minor detail, but it can make or break the success of an RFID solution: choosing the right IP protection class.

If hardware or transponders are not selected to suit the actual environmental conditions, this can lead to considerable difficulties during operation. These range from interference caused by unfavorable material influences to damaged devices and complete system failures. Such situations jeopardize the desired process stability and increase costs instead of reducing them. To avoid these risks, it makes sense to rely on the experience of an integrator before implementation. They can identify potential stumbling blocks at an early stage, realistically assess the operating conditions, and ensure that the selected components will function reliably in later live operation.

SIGMA has already successfully deployed RFID systems under the most severe conditions (foundries, paint shops, outdoor forklift systems, etc.) and draws on many years of experience to ensure that systems remain rock-solid even after implementation and operate reliably without failures.

![[Translate to English:] Palettenreinigung [Translate to English:] Palettenreinigung](/fileadmin/_processed_/5/b/csm_palettenreinigung_81b99145e4.jpg)