What is OEE - and why is it so important?

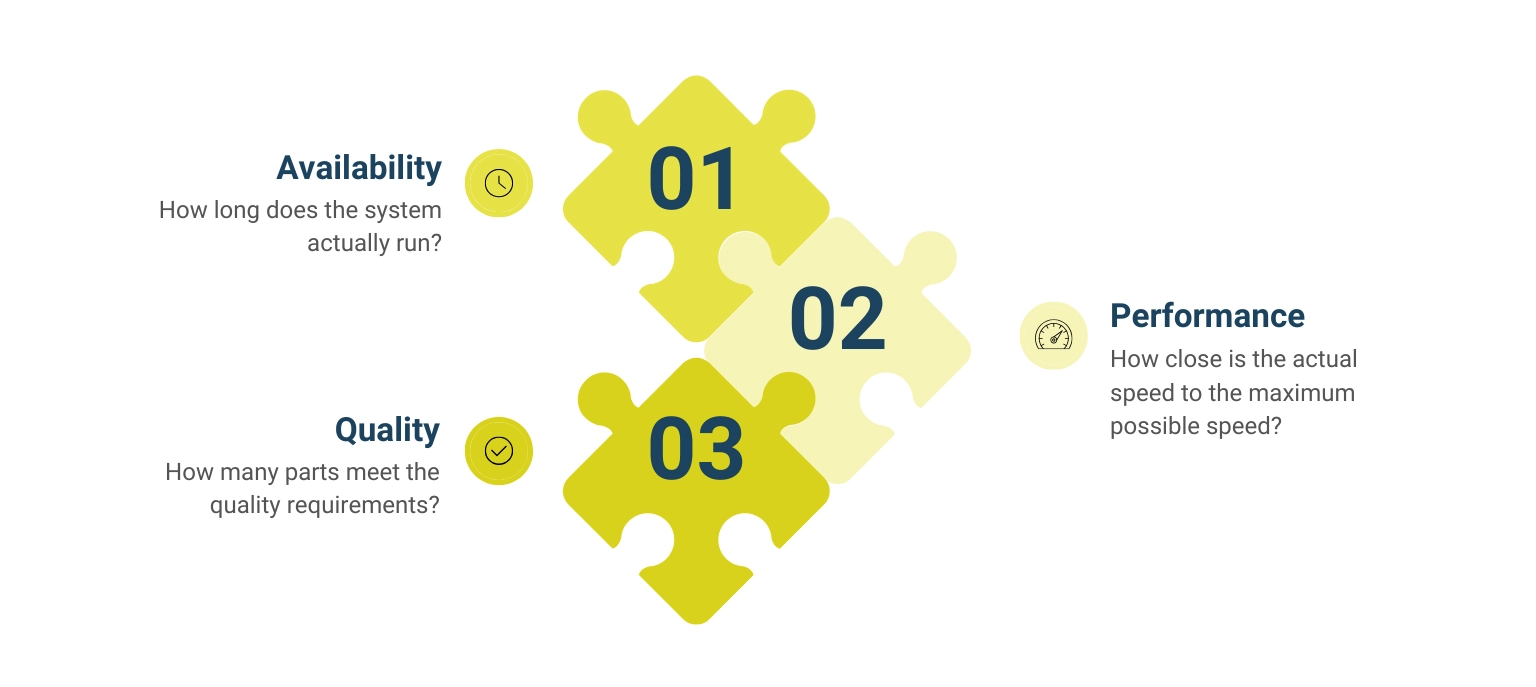

OEE (Overall Equipment Effectiveness) is the most important indicator for evaluating the productivity of production facilities. It measures how efficiently machines are actually used and consists of three factors:

- Availability: How long does the system actually run?

- Performance: How close is the actual speed to the maximum possible speed?

- Quality: How many parts meet the quality requirements?

Formula: OEE = Availability x Performance x Quality

A high OEE means: less downtime, higher utilization, and better quality.

The challenge: Why traditional OEE measurements are incomplete

Many companies still calculate their OEE manually—using Excel spreadsheets or incomplete machine data.

This leads to typical problems:

- Incomplete data collection: Manual entries are prone to errors.

- No real-time data: Problems are often detected too late.

- Lack of transparency: Downtime, setup times, and rework remain invisible.

- Missed opportunities: Planned downtime offers untapped potential for optimization.

The result: the actual efficiency of your production remains unclear.

The solution: OEE optimization with RFID technology

RFID (Radio Frequency Identification) automatically collects production data in real time. This gives you a complete, objective, and transparent picture of your OEE—at any time and without manual effort.

How RFID improves your OEE:

Materials, tools, and products are automatically recorded.

![[Translate to English:] Automatisierung [Translate to English:] Icon Automatisierung](/fileadmin/AutoID_RFID/rfid-tracking/RFID-Gate/nutzen_prozesssicherheit_icon.jpg)

Reduces human error and improves data quality.

![[Translate to English:] Problemerkennung [Translate to English:] Icon Problemerkennung](/typo3conf/ext/sigma_template/Resources/Public/images/placeholder.png)

Downtime and deviations become immediately visible.

![[Translate to English:] Icon Produktionsplanung [Translate to English:] Produktionsplanung](/fileadmin/AutoID_RFID/rfid-tracking/traceability/icon_lossgroesse_1.png)

Bottlenecks are avoided and resources are used more efficiently.

![[Translate to English:] Icon Wartung [Translate to English:] Wartung](/typo3conf/ext/sigma_template/Resources/Public/images/placeholder.png)

Maintenance based on actual machine data – rather than according to a calendar.

The result: higher OEE through increased availability, performance, and quality.

Predictive Maintenance & OEE: Efficiency through predictive maintenance

Predictive maintenance uses sensor data and AI analytics to identify maintenance needs at an early stage. This allows you to improve your OEE on several levels:

- Reduction in unplanned downtime: higher availability

- Optimized maintenance intervals: better performance

- Early quality control: less waste

- Longer machine life: lower costs

This makes your OEE measurement the basis for proactive, stable production.

Our solution: Live OEE dashboards & Power BI

With our live OEE dashboards, you can keep an eye on your production at all times – visually, intuitively, and in real time.

Features at a glance

Visualization & Analysis

- Interactive charts for availability, performance, and quality

- Trend and time series analyses

- Customizable dashboards for lines, shifts, or plants

- Heat maps for analyzing machine conditions

- Traffic light systems for quick detection of critical conditions

Data acquisition & machine data

- Automatic component detection at the assembly station

- Recording of downtimes

- Processing of machine data (e.g., data via OPC UA)

- Target and actual cycle times

Quality & error transparency

- Detection and recording of clearly evaluable error causes

- OK / NOK feedback

Power BI integration:

- Connection to ERP, MES, and cloud systems

- Automatic data updates

- Better order prioritization and planning

- Control of responsibilities through transparency of error causes

- Intuitive operation—no programming knowledge required

- Scalable and secure—from specialist departments to management

With the help of our technologies, production data from RFID, barcode, and camera systems can be automatically collected, processed, and visualized—for seamless, real-time OEE analysis.

Conclusion: Your OEE – measurable, controllable, optimizable

The future of OEE measurement is digital, automated, and transparent.

With our solutions, you can lay the foundation for sustainable performance improvement in your production.

We will be happy to present solutions for your industry and your processes. Talk to the specialists for SMEs.

request now