Functions of RFID readers

RFID readers play a crucial role in the seamless traceability of products. They are used for identification and communication by emitting electromagnetic waves that are received by RFID tags. These tags use the energy of the waves to send their stored information back to the reader.

![[Translate to English:] Datenübertragung [Translate to English:] Icon Datenübertragung](/fileadmin/AutoID_RFID/rfid-tracking/RFID-Gate/richtung.png)

RFID readers capture the information from the tags and transmit it to a central system for further processing and analysis. This capability enables real-time monitoring and tracking of objects.

![[Translate to English:] Rückverfolgbarkeit [Translate to English:] Icon Rückverfolgbarkeit](/fileadmin/AutoID_RFID/rfid-tracking/vorteile_rueckverfolgbarkeit_icon.webp)

By providing accurate and up-to-date information on the location and status of objects, RFID readers promote complete traceability. This is particularly important in complex supply chains, where accurate tracking of goods movements is crucial for efficiency and security.

Applications of RFID readers

RFID readers have a wide range of applications in logistics and the supply chain, including

![[Translate to English:] Echtzeitverfolgung [Translate to English:] Icon Echtzeitverfolgung](/typo3conf/ext/sigma_template/Resources/Public/images/placeholder.png)

Real-time tracking

They enable the monitoring of goods movements along the entire supply chain, which helps to control stocks and minimize losses due to theft.

![[Translate to English:] Lager [Translate to English:] Icon Lagerverwaltung](/fileadmin/AutoID_RFID/rfid-tracking/traceability/icon_lagerverwaltung.png)

Warehouse management

In warehouse management, RFID readers facilitate the efficient recording of stock levels, significantly reducing manual effort.

![[Translate to English:] Gesundheitswesen [Translate to English:] Icon Gesundheitswesen](/fileadmin/AutoID_RFID/rfid-tracking/traceability/icon_gesundheitswesen.png)

Healthcare

In the healthcare sector, RFID readers can be used to track patients and medical devices, increasing safety and efficiency in hospitals.

![[Translate to English:] Produktion [Translate to English:] Icon Produktion](/fileadmin/AutoID_RFID/rfid-tracking/traceability/icon_produktion.png)

Manufacturing

To ensure seamless traceability in the manufacturing process, RFID readers are used to track components and products. This improves quality assurance and minimizes production errors. They are also used to track tools and machines in order to optimize their use and maintenance.

Types of RFID readers

RFID reader from Turck

These readers are used for RFID-based traceability applications. They enable RFID tags to be read in order to track the movement and status of objects on the store floor.

Q120

Size | Protection class | Features | Area of application |

130 x 120 x 60 mm | IP67 | Combines circularly polarized antenna and all electronics in a space-saving aluminium housing, temperature range -20 to +50 °C | Suitable for confined installation conditions (e.g. conveyor automation), packaging area, detection of input and output movements |

![[Translate to English:] Q120 [Translate to English:] Turck Reader Q120](/fileadmin/AutoID_RFID/rfid-tracking/traceability/turck_q120.webp)

Q175

Size | Protection class | Features | Area of application |

200 x 175 x 60 mm | IP67 | Robust design for use in harsh industrial environments, reading range enables detection of up to nine empty pallets stacked on top of each other | Logistics and supply chain, production, pallet tracking |

![[Translate to English:] Q175 [Translate to English:] Turck Q175](/fileadmin/AutoID_RFID/rfid-tracking/traceability/turck_q175.webp)

Q180

Size | Protection class | Features | Area of application |

300 x 180 x 61.7 mm | IP67 | Also suitable for metallic environments or in the presence of liquids, parameterization, UV-resistant, integrated web server, 4 connections for passive UHF RFID antennas | Logistics and supply chain, manufacturing (complex production processes), food industry |

![[Translate to English:] Q180 [Translate to English:] Turck Q180](/fileadmin/AutoID_RFID/rfid-tracking/traceability/turck_q180.webp)

Q300

Size | Protection class | Features | Area of application |

300 x 300 x 61.7 mm | IP67 | Integrated web server with reader, parameterization, UV resistance, connection of up to 4 external UHF antennas, reading range up to 10 m, bulk detection | Logistics and supply chain, manufacturing |

![[Translate to English:] Q300 [Translate to English:] Turck Q300](/fileadmin/AutoID_RFID/rfid-tracking/traceability/turck_q300.webp)

RFID reader from Kathrein

RRU 1400

Size | Protection class | Features | Area of application |

175 x 167 x 40 mm | IP40 | 30 dBm UHF RFID reader, PoE connection, Supports EPC Gen2v2/ISO 18000-63, Linux operating system, 256 MB RAM | Indoor applications: Logistics and supply chain, manufacturing, access control |

![[Translate to English:] Kathrein Reader [Translate to English:] RRU 1400](/fileadmin/AutoID_RFID/rfid-tracking/traceability/rru-1400-front.webp)

![[Translate to English:] Kathrein Reader [Translate to English:] RRU 1400 Back](/fileadmin/AutoID_RFID/rfid-tracking/traceability/rru-1400-back.webp)

![[Translate to English:] Kathrein Reader [Translate to English:] RRU 1400 Anschluss](/fileadmin/AutoID_RFID/rfid-tracking/traceability/rru-1400_anschluss.webp)

RRU 4500

Size | Protection class | Features | Area of application |

300 x 300 x 71 mm | IP67 | Highest reading performance in harsh environments +33 dBm output power, Integrated dual-core 800 MHz PC, Wi-Fi and BLE, High-secure memory module, Supports up to 32 reading points with KRAI | In harsh environments and outdoor areas, complex process environments, IoT applications, logistics, production |

![[Translate to English:] Kathrein Reader [Translate to English:] RRU 4500](/fileadmin/AutoID_RFID/rfid-tracking/traceability/rru-4500-front.webp)

![[Translate to English:] Kathrein Reader [Translate to English:] RRU 4500 Back](/fileadmin/AutoID_RFID/rfid-tracking/traceability/rru-4500-back.webp)

![[Translate to English:] Kathrein Reader [Translate to English:] RRU 4500](/fileadmin/AutoID_RFID/rfid-tracking/traceability/rru-4500-anschl.webp)

RFID reader from Sick

RFU 620

Size | Protection class | Features | Area of application |

137,4 x 130.8 x 55,3 mm | IP67 | Operation within a wide ambient temperature range possible, Circular polarization, Read range up to 2 m, Supports EPCglobal UHF Class 1 Generation 2 and ISO/IEC 18000-6 C | Industrial and logistics areas, material flow control, product tracking |

![[Translate to English:] Reader RFU620 [Translate to English:] SICK RFU620](/fileadmin/AutoID_RFID/rfid-tracking/traceability/sick_rfu620.webp)

Source: SICK AG

RFU 630

Size | Protection class | Features | Area of application |

239 x 239 x 64 mm | IP67 | Large read ranges of up to 10 m, Integrated process logic for stand-alone solutions or network operation, 3 connections for external antennas, Bulk detection, Adjustable transmission power | Logistics and supply chain, manufacturing (complex production processes), vehicle identification |

![[Translate to English:] RFU630 [Translate to English:] SICK RFU630](/fileadmin/AutoID_RFID/rfid-tracking/traceability/sick_rfu630_front.webp)

Source: SICK AG

![[Translate to English:] SICK Reader [Translate to English:] RFU630](/fileadmin/AutoID_RFID/rfid-tracking/traceability/rfu630_persp_2.webp)

![[Translate to English:] SICK Reader [Translate to English:] RFU630](/fileadmin/AutoID_RFID/rfid-tracking/traceability/rfu630_persp.webp)

RFU 650

Size | Protection class | Features | Area of application |

400 x 252 x 70 mm | IP67 | Robust design for use in harsh environments, Long read ranges of up to 10 m, Circular polarization, High reading speeds, Direction detection | Harsh industrial and outdoor environments, logistics, vehicle identification, extensive logistics and production environments |

![[Translate to English:] SICK Reader [Translate to English:] RFU650](/fileadmin/AutoID_RFID/rfid-tracking/traceability/sick_rfu650_2.webp)

Source: SICK AG

![[Translate to English:] SICK Reader [Translate to English:] RFU650](/fileadmin/AutoID_RFID/rfid-tracking/traceability/sick_rfu650.webp)

Cost savings through the use of RFID readers

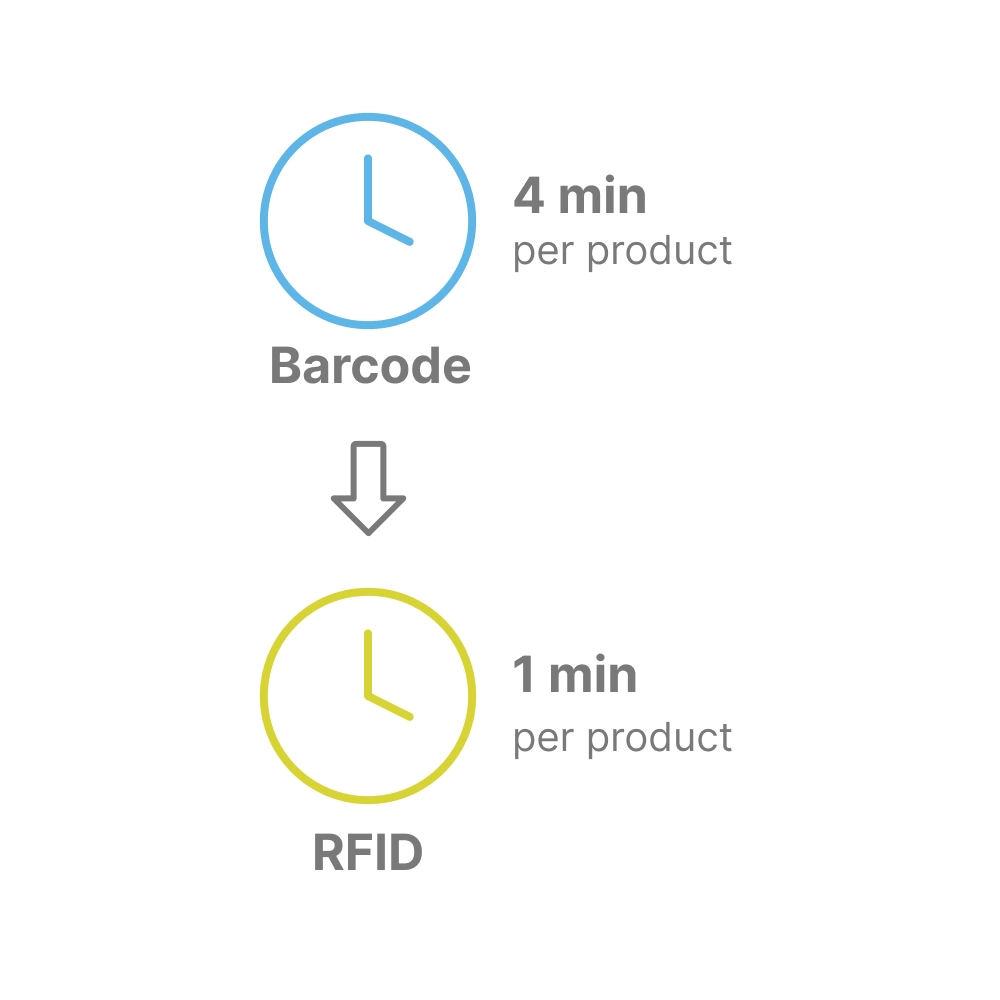

Process | Barcode | RFID |

Component Goods receipt | 1 | 1 (one-time labeling) |

Process steps in production | 5 | 5 (no new label required) |

Component shipping | 1 | 1 (end customer barcode shipping label) |

Costs for labeling | 7 x 2 ct = 14 ct | 13 ct per RFID label + 2 ct per barcode shipping label = 15 ct |

Time for labeling and recording | 4 min per product | 1 min labeling + automatic detection |

Litigation costs p.a. | Barcode | RFID |

Labeling | 0.14€ x 200 components produced daily x 250 working days = 7000€ | 0.15€ x 200 components produced daily x 250 working days = 7500€ |

Time required | 200 components produced daily + 4 min = 800 min | 200 components produced daily x 1 min = 200 min |

Annual labor costs | 14 hours x 25€ wages x 250 days = 87.500€ | 3.5 hours x 25€ wages x 250 days = 21.875€ |

Total | 94.500€ | 29.375€ |

Best practices for implementing and maintaining RFID readers

- Ambient conditions: Select locations that are as free as possible from highly reflective surfaces such as metal or liquids, as these can cause signal interference. Locations near such materials should be specially shielded. In areas where metal or liquids are unavoidable (e.g. tool tracking in manufacturing plants, chemical or food processing), use specially developed “on-metal” tags or chemical-resistant, epoxy-coated tags. Spacers can also help reduce signal interference from reflection by positioning the tag slightly above the metallic surface.

- Optimal distance and range: Ensure that the reader is installed in an area that provides full coverage, taking into account any obstructions that may affect range or accuracy.

- Alignment and angle: Position the RFID reader and antenna at the correct angle (usually 90°) to the RFID tag to ensure high accuracy and range. The orientation of the antenna should be matched to the specific polarity of the RFID tags (linear or circular polarity) to minimize signal loss.

- Antenna arrangement: If necessary, use multiple antennas or high gain antennas to ensure full coverage in larger or more complex environments.

- Data encryption and authentication: Use encryption for wireless data transmission to protect sensitive information from potential threats. Implement authentication protocols to ensure that only authorized users can access the data.

- Interference control: Avoid interference with other wireless devices operating on similar frequencies to minimize read errors and improve system stability

- Interference from other electronic devices: Shield RFID components or position them far away from interfering devices such as WLAN routers or other radio devices to prevent signal interference.

- Compatibility with IT systems: RFID systems should be fully compatible with existing software and IT infrastructure (e.g. ERP systems). Software interfaces should use standardized architectures such as RESTful APIs based on established protocols such as http to enable smooth integration.

- Staff training: Employees should be familiar with the handling and maintenance of the RFID system in order to minimize errors and maximize efficiency.

- Correct antenna selection and alignment: Select antennas with high gain for long ranges or align the antennas precisely to the reading points. Linear antennas offer a greater range with precise alignment, while circular antennas are more flexible in their orientation.

- Calibration and maintenance: Calibrate the readers regularly to maintain accuracy and minimize the effects of wear and tear. Maintenance includes cleaning the antennas and checking for physical damage.

- Optimization of reading modes: Adjust reading modes and frequencies based on the environment and reading requirements to ensure accurate and fast reads. In areas with high tag density, a mode can be selected that allows multiple tags to be read simultaneously.

We will be happy to present solutions for your industry and your processes. Talk to the specialists for SMEs.

request now