The digital product passport: What companies can expect

The EU is getting serious about the circular economy. One of the central building blocks: the Digital Product Passport (DPP). According to the Federal Ministry for the Environment, Nature Conservation, Nuclear Safety and Consumer Protection (BMUV), it is intended to help use resources more efficiently, create transparency and make sustainability measurable. The DPP will become mandatory for the first product groups as early as 2027. What does this mean for the industry?

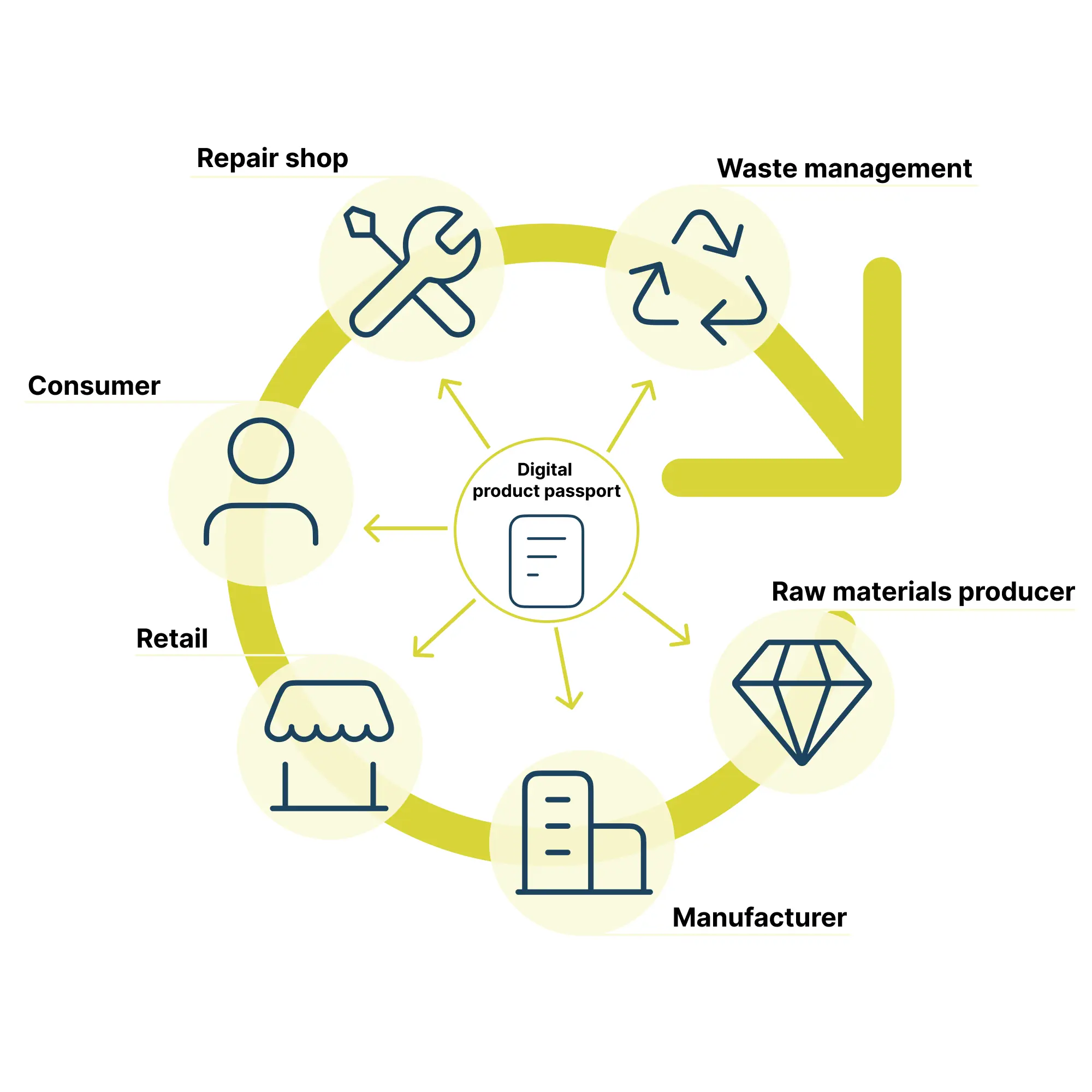

The Digital Product Passport is essentially a structured data set that is assigned to a product. It documents the entire life cycle - from raw material extraction through production and use to recycling. The assignment is made using digital identification technologies such as RFID transponders. RFID in particular offers new opportunities for the industry.

RFID: Digital identity that stays

RFID solutions enable the identification of objects without visual contact. Unlike QR or barcodes, they work without visual contact, are more robust, reusable and store more information. RFID transponders really come into their own in production or logistics processes with high levels of stress (e.g. heat, dirt, washing processes).

Typical advantages of RFID in relation to DPP:

- Unambiguous identification of a large number of products at once (bulk readings)

- Automated data updating along the supply chain

- Durability even with high requirements

- Storage of process and status data (e.g. machine data)

An RFID transponder thus becomes the digital DNA of a product - and carries all the information required in the DPP.